Tunnel Oven

Our tunnel ovens offer exceptional versatility and high-performance capabilities for a

wide range of bakery products, including cakes, Swiss rolls, toast bread, steamed cakes,

bagels, pizzas, pastries, pies, biscuits, rusks, and more. Designed to meet the diverse

needs of industrial and smaller-scale bakeries, our ovens are available in various

configurations, such as stone plate baking belts, heat convection systems, and integrated

steam generators, ensuring optimal results across different food products.

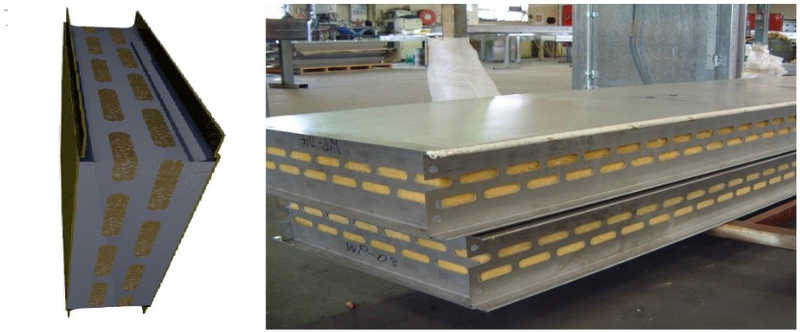

Constructed with durability in mind, our ovens feature insulated metal wall panels that

are ten times stronger than the average, providing excellent thermal retention and lasting

reliability. These panels, measuring 685mm in width and 100mm in thickness, are made

from 3mm sheet metal and contain ceramic fiber insulation, capable of withstanding

high temperatures up to 1260°C. The use of high-quality materials guarantees long-

lasting performance, even under the most demanding conditions.

Our burners utilize a "zero pressure" gas system, igniting and burning a gas/air mixture

to achieve precise temperature control. The gas is supplied to the gas/air mixer at

nominally zero pressure, with the air provided at a positive, controlled pressure. By

adjusting the air pressure, the flame intensity and heat input to the baking chamber can

be fine-tuned. The system is compatible with natural gas, town gas, or LPG, offering

flexibility in fuel options.

The gas supply is regulated by a comprehensive "gas train" system, designed for both

safety and efficiency. This includes:

•A manual shut-off valve for secure gas control•Two automatic shut-off valves for added safety

•A gas filter to ensure clean fuel supply

•A zero-pressure gas governor for precise regulation

•High and low gas pressure detection for system monitoring

•Pressure gauges for both the gas inlet and outlet

•A gas valve tightness proving facility to check for potential leaks

•Main gas pipes and a gas distribution system to deliver fuel across the oven

Gas is distributed to each zone via header pipes at both the top and bottom of the oven,

connected to each burner through flexible hoses, solenoid valves, and gas/air mixers for

efficient and reliable operation.

Our tunnel ovens are engineered to provide consistent, high-quality results for a variety

of bakery products, combining advanced technology, robust construction, and safety

features to meet the highest standards in the food manufacturing industry.

Insulated Wall Panels

Walls are made of insulated metal wall panel ten times stronger than the average. Ensuring that our product will not only withstand the test of time, but also anything else you can throw at them. Typical Panels measure 685mm wide and 100mm thick. Made with 3mm sheet metal.Ceramic fiber insulation, high temperature 1260°C